Managing Risks When Transporting Shipping Containers

When it comes to moving or delivering the shipping containers in-between states or across the border, figuring out the logistics can be challenging for any business.

After all, transporting a large, highly loaded shipping container is not as simple as delivering a mini package. There’s a complicated web of people, systems and infrastructure at work. And if somehow the plan does not meet all the regulatory standards, you can run into snags that end up costing your money, time and, most importantly, customers.

So if transporting shipping containers is one of your business’s everyday operations, make sure to take some key risk factors into account to get ahead of the game.

How is risk assessment important?

If you are running a supply chain, a proper risk assessment can be a helpful addition to your operations. Because the odds are high that to manage the transportation tasks properly, you need to work with a third-party logistics provider. So when the success of your entire supply chain is dependent on the carrier to hand over the products in good condition to the end-users, identifying the possible risks early in the transportation process can definitely have the most impact. And this will benefit you to avoid profit loss, meet safety standards, safeguard your company image and maintain customer satisfaction. Or else, lack of prior risk assessment can pose a significant risk making the merchandise suffer from accidents or losses.

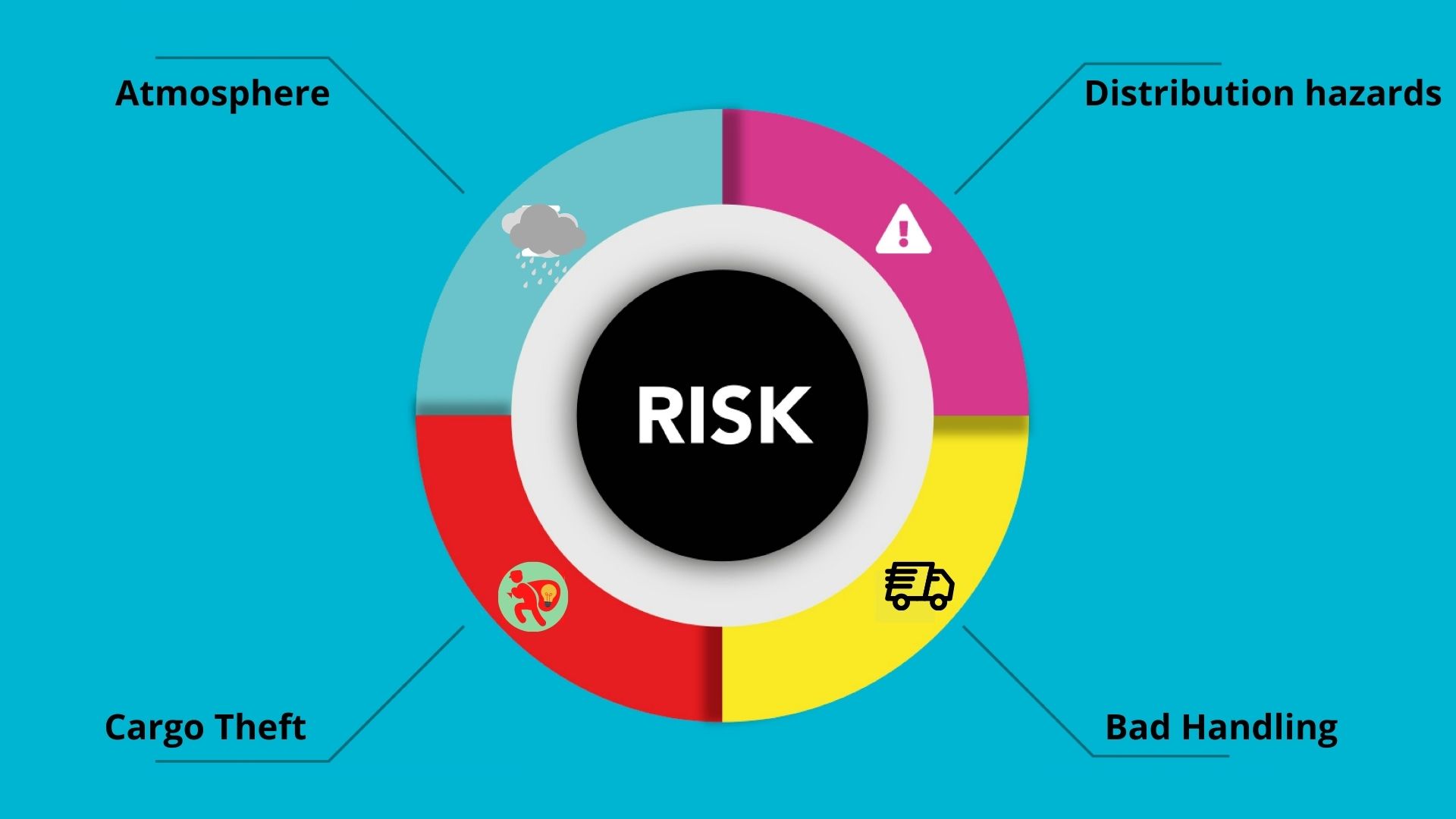

Some common risk factors related to transporting shipping containers

So to come up with a mitigation strategy, the first step is to identify and prioritise risks. Here are some common areas of risk associated with transporting goods in shipping containers.

1. Bad handling

Handling refers to the process of picking, packing, loading and offloading cargoes or containers while controlling the movement, storage and protection of items. And often, lousy handling causes accidents leading to several slips and trips, which could prove costly. For example, if you are supplying fragile materials while in transit, there is always a chance of damage if they are not treated as such. And since in the whole transportation process a product is handled by many people, the chances of improper handling and unwanted damages grow even higher, be it for being dropped on accidents by delivery drivers or mishandling while loading.

2. Atmosphere conditions

Temperature, humidity and altitude are a few names that can quickly produce adverse effects if the system is not correctly observed. Changes in the atmosphere while passing through various climate zones can cause container rain or container sweat. Especially for shipping items requiring a particular temperature or humidity requirements like foods or pharmaceuticals, the atmosphere condition is a significant concern. For example, when transporting goods across borders, condensation occurs due to the fluctuation of day and night temperature, which might drip down onto the cargo and causes damage to the goods.

3. Cargo theft

Mostly at rest stops, parking lots, drop lots or areas where cargos are left unattended, cargo thieves target truck container transport full of merchandise to steal the goods. However, though thieves are known to jump on trailers looking for high-value cargo for direct theft, sometimes employees with knowledge from the ‘inside’ also get involved in this cargo theft operation by providing transportation information to others. Also, hijacks, piracy and cyber-attacks are some other common tactics thieves use to steal commodities and breach and track systems.

4. Other distribution hazards

Packaging distribution risks include vibrations, compressions or accelerations. Various companies use a number of different transport modes, and the vehicle suspension system produces its own natural resonant frequencies, which cause boxes to shift from here to there when loaded improperly. Also, the up and down motion of bumps and jolts from the roads can lead to breakage and deterioration. Sometimes packaging that can’t withstand high compression forces fails to protect the goods. Then during the transportation, sudden acceleration, curves, stops or shifts in direction can cause a poorly packed load to tilt more.

Ways to minimise risks associated with container shipping

Below mentioned points are some of the risk management strategies you can add to your risk management plan.

i) Identify and prioritise risk

Understanding the types of risks your business might face or risks that already exist is definitely the first step. Such as there is some sort of risks related to internal processes, including information, strategy, and data safety, or there are risks associated with the logistic company. So once you successfully identify the area of risk, take all the preventive measures and execute the action plan. Or else leaving any loopholes unaddressed can turn the progress more complex while maximising the possibility of risks.

ii) Trained and qualified personal

You have to ensure that the personnel involved in the product handling and distribution centre are trained and qualified enough to provide a well maintained and secure packaging and distribution process. So when engaging a new employee, carrier or new contractor, it is a requirement to conduct a thorough background check. For example, the carriers’ track records and the drivers’ training and accident records could be one of the first things you can put your focus on.

iii) Adoption of advanced technological solutions

From sensors to trackers, there are a bunch of technological tools you can implement to counter risks when transporting shipping containers. A GPS monitored container transport is always a good option to track the vehicles and to get estimated delivery times. Also, attaching temperature sensors can ensure the new condition of your goods until delivery and adding sensors during packaging can help you to prevent product losses or damages by warning rough handling. Even there are electric locks, tamper-resistant seals and electric steering available that you can add to ensure extra safety during transportation.

iv) Proper shipping container packing

Since each container of goods goes through many loading or unloading processes, which entails a number of activities, you need to ensure your container is actually ready to be moved. When putting products or goods into your shipping container, get it to proper weight. Then place, evenly distribute and secure each of the contents or else uneven packaging can cause lots of shock and movement to the contents while loading and unloading. You can also use padding materials to keep your container ready to deal with impacts and vibrations or water-resistant paper to reduce the changes in environmental issues.

v) Maintaining safety practices

Give specific attention to cargo thieves and cyber frauds. If required, you can provide training to staff with particular emphasis on cargo theft consciousness and avoidance so that they can punctually identify threats and execute solutions. You should keep all the valuable information confidential, including the time, date, route and place of delivery. Before the journey, check whether the containers are sealed properly or not, and instruct your driver to use direct or single-trip deliveries if possible. Also, take up insurance to bounce back any sort of risk without experiencing loss.

How does investing in container shipping transport services turn beneficial?

With all the packing, handling, environmental and any sort of threats, it is always a wise choice to form a partnership with a container shipping transport service provider when it’s about managing risks related to transporting shipping containers.

After all, when you are already busy running businesses that ship nationally or internationally, focusing on the risk factors and ensuring a monitoring system that covers the entire transportation process seems overwhelming. And definitely adequately trained staff, special handling, packing and managing, skilled drivers and available options for any sort of industries are some of the extra bonuses that a professional transport company comes with. No doubt, exactly, these are the facilities that you need to manage risks when transporting shipping containers in a far less stressful way.

Here, OFE refrigerated transport, based in Melbourne, with years of experience in working with retailers and suppliers of all sizes, takes pride in being a leading container transport provider. From GPS monitored container trucks to skilful drivers and staff, product handling to storage facilities, OFE offers everything while collecting and delivering containers. So no matter what kind of niche you fill, contact OFE to experience quality shipping service while skipping any possible risks.